Warping: from the origin of the problem to solutions

It has been several weeks since I see the same disillusioned spring posts (I understand them), often for lack of knowledge, victim of failure of first multiple and varied layers, of parts that take off … In short: the disaster.

All the causes go there: a not warm bed, a poor quality filament, a tragic and shameful update etc.

Active on Facebook, I tirelessly reject the same doctrine, effective for those who dared to change their printing paradigm.

My friend Printer Mathieu, grand master of these places, having authorized me to proser on his super blog, first, I take advantage of having my keyboard in my hands to thank him and for the rest, I am going to impose a substantial article for you …

Yes, you are going to bleed with your eyes:

"" “Whaaaaa … the pavement … He cracked this one !!!

There is not even an image! ”

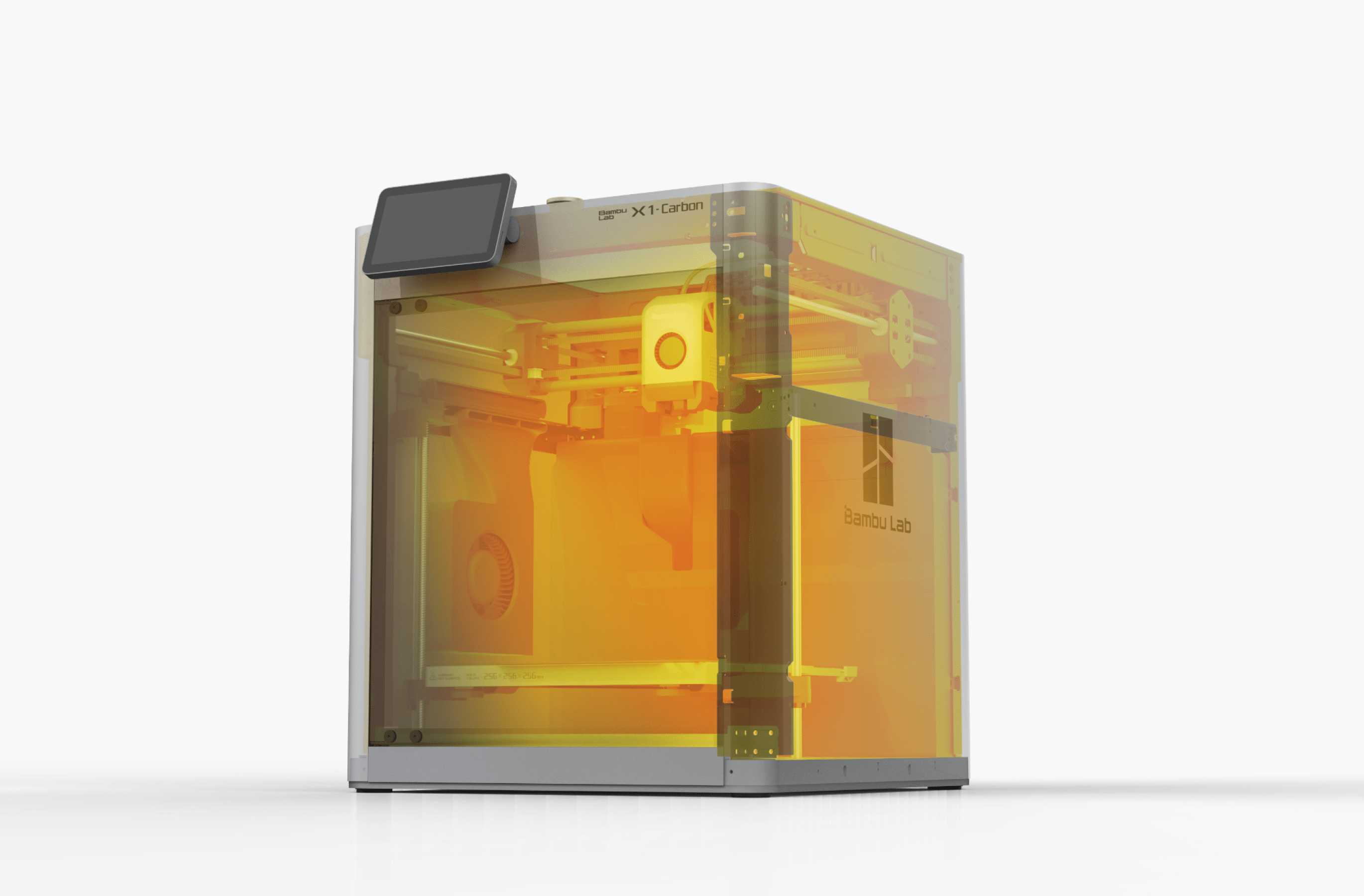

I hear you from here … 3DP FDM is wonderful with Bambu Lab, I am the first to recognize it.

For beginners, our favorite brand is incredible.

Only, 3DP FDM, it’s still high engineering aerobatics.

And solve all the complexity of our machines with a vulgar “problem-solutions” painting, without explanation, it rhymes with nothing.

The literature on the subject is very mostly English and quite substantial.

It was by reading this gibberish that I ended up learning to solve the same problems you encounter.

So that’s it.

CHAETTH YOUR TRUTINES AND YOU SAURE SOUD YOUR WARPING PROBLEMS.

Warping: What is that?

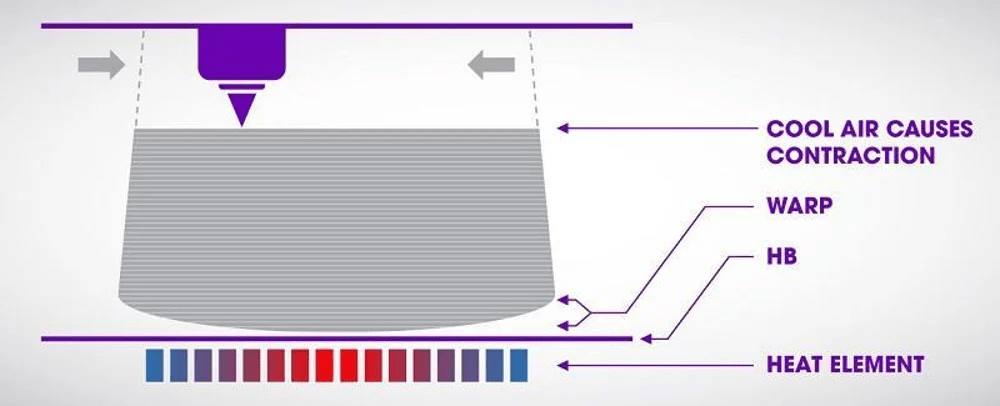

Warping or left -handing is often described on reference sites as a 3D printing problem which consists of a detachment of the first layer.

However, the detachment of the bed of the BED during printing is however only one of the many symptoms when the warping disturbs our impressions.

Do the experienced printers face the Warping?

YES !

But most of the time, the problem will be quickly solved and better still, it will be anticipated.

But how do they do it?

We will try to tackle the question.

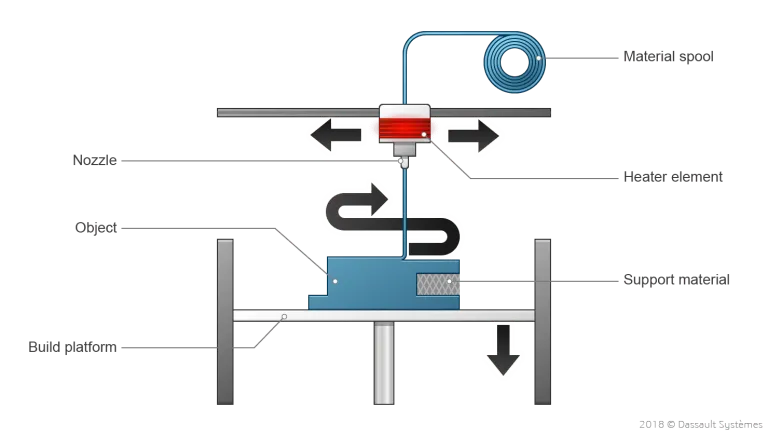

The basics of FDM technology

Two fundamental times are to be taken into account in the creation of 3D object in thermoplastic by depot of melted filament:

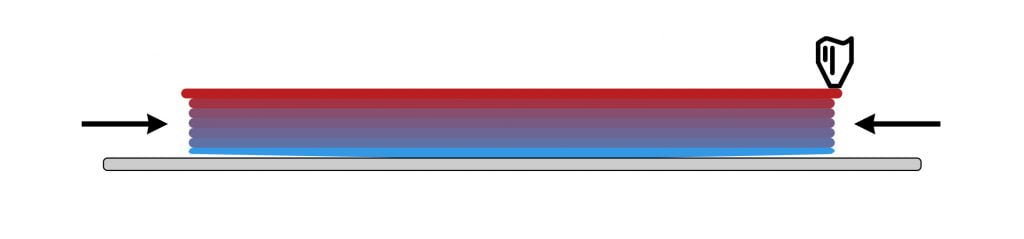

We heat the filament and give shape to our object;

The room is cooled to give it solidity while retaining its dimensional stability.

We melt PETG in a small cavity heated to 270 ° (for example), the melted PETG is placed on a plate heated to 70 ° (for the example).

Layer 1: temperature close to that of bed;

Coach 2: it will be less hot than the 1st;

Coach 3: It will be less hot than the 2nd;

Layer 4: It will be less hot than the 3rd;

etc.

etc.

Successful cooling

The most we go up, the most our material cools.

Attention !

It doesn’t matter, that’s how FDM works.

What we want in this observation is homogenize cooling on the entire room.

This homogeneity of cooling will give you a dimensional satisfactory piece and will have an impact on its general solidity, without major structural fragility.

The keywords to remember: adequate cooling (neither too slow nor too fast), uniform, homogeneous.

Ready cooling

If our PETG piece cooled too quickly and/or in a non -homogeneous manner, we face dimensional disturbances because the material will retract.

This phenomenon will shoot the diapers so much that it will raise the first layer.

It’s the warping!

And sometimes the phenomenon is fast enough to blow up your pieces from the first layers.

Not only does it take off, but in addition, you will hear that if this steep cooling generates phenomena of material withdrawal, you will face dimensional disorders.

The warping can also touch your parts on the high floors and dissociate layers.

Diagnosis and solutions

The major cause you expect so much: it is not the update, it is not the weak quality of your filament … It is a problem of local weather.

Let me explain: your bed heated to 50 °, nozzle at 220-230 °, tropical climate.

It prints well, everyone is happy.

And you open the door to your cat who harass you.

Cold air penetrates the room, and your tropical climate suddenly changes with icy air flows that cross printing.

For the owners of the door adept at the door and open window for the PLA, the colder air enter your printer by these mega openings: it is a thermal bridge!

This bridge will be captured by your auxiliary fan + your nozzle fan and will blow a cold air on your room.

The cold air does not disturb the previously homogeneous cooling of your room: you have understood, it’s the Warping.

PLA, PETG, ABS, ASA … All are concerned.

If you wanted to close the door and the upper window of your box, very good idea.

The thermal bridge will always be under the aegis of your rear fan, and it will return through the poop hole, capture by the auxiliary and bam fan … the same.

We throw ourselves!

With small ailments, big remedies when it warpe!

Closed box door;

Closed upper window;

50-60% box fan;

Auxiliary fan as usual;

Nozzle fan as usual (100% for the PLA whatever happens)

Control as long as thermal bridges can be made of the location of your accommodation where you print.

Drastically slow down the installation of the first layer and the following ones too.

Trying, on a small print: a benchy boat, the first layer of which is very demanding.

It consumes little filament.

If new failure, lower the extractor fan to 20-30% and still retain.

This cursed auxiliary fan smokes this new print?

It is that it is necessary to reduce its pro-Gre-Issi-Ve-Ment power, nothing else.

Porte and window closed, the thermal bridge is through the poop hole and the window.

It is the extractor fan that generates the air entrance into the box, and our awful thermal bridges go through the simplest path.

My faster method: I launch printing with a 0%extractor.

I monitor the behavior of the temperature of the box on the first layers.

And I increase the power of the fan gradually extracting, until I find the right balance: enough fresh air to ventilate my box, and just what it takes not to do my room.

I hear you: “On the Wiki Bambu Lab, they tell us that we have to print the PLA with the open door and the window too.

I know … and they are right, they are technically right.

Although … (we re -register another day).

I summarize quickly with my stat ’: 500 hours of print on X1C, 100% of my prints all materials combined prints and closed window.

I clogged once and it was my fault (0% assistant for PLA on a very demanding room …).

In summary, printing PLA in a closed box, with ventilation, that does not matter, I see there any risk of damaging my machine.

My secret of Polichinelle?

Well, I slowly print, the technical parts even more because the retraction movements tend to overheat your hotel with the risk of clogging.

Slow printing = impeccable quality!

This is my credo: Print slowly is a source of economy.

I print in a closed checkout, all the time, rather slowly and even more when the weather conditions are difficult (-10 ° a few days ago).

On Bambuhandy, I regularly monitor the temperature of my box.

If it climbs a little too much, I put a small 10-20% on the rear extractor fan.

I’ve already risen 40% with ASA to avoid the 70 ° that put the hotel in safety (never lived, I read it on an English forum): no warping.

A1 owner

If you print on your desktop and open a nearby window … Gare you … unless you imprison your machine in a cupboard, in a box, even artisanal, taking care to avoid these damn thermal bridges.

Very clearly, I was like you, equipped with a Sidewinder X1, open open.

Well very clearly, after having gone mad, to believe that I was cursed by the 3DP god, I ended up understanding the causes of my inconvenience.

And winter was part of the equation … and I experienced periods when I did not start my machine in the way for lead.

The box of my X1C is a miracle, but its box will not save us from the warping.

For you, you will have to take care not to bring in cold air into your printing place.

You only have that to do if you cannot put your machine under the box.

One final important information: when I turbine with my old Sidewinder X1, I imprinted with a disconcerting ease of the Greentec Pro (Extrudr brand).

A technical filament that costs an arm.

Never a single incident!

A absolutely crazy cooling stability, whatever the weather conditions of the printing, I have no memory of an idle Warping.

Filaments that cost expensive a lot of things.

Yes, 3DP, that’s it.

It’s the hassle.

Do not imagine that the best printers lay 100% perfect parts, they do not show the kilo of failures they undergo.

3DP is also spending hours watching the machine work and understanding what’s going on.

At first, you have to go through these times of testing and learning your machine and its climate.