Threading filament test

Very often the filaments are made in China, very rarely in Europe, but there are some filament manufacturers in France, such as the company [Filform] (https://www.filforme.com/)

.

was created by 3D printing enthusiasts, this company is based in Collonges near the Swiss border.

They make their filaments in their premises thanks to an extrusion line, to increase their production, a new line is scheduled for 2025.

In their catalog, there are several types of filaments: PLA, ASA, ABS, PETG in several colors.

The composition of their filaments only uses highly certified and safe raw materials.

To have more detailed on filiform: [https://www.filforme.com/content/4-quommes nousquoquerîtps://www.filforme.com/content/4-quommes nos)

Filiform contact details:

Website: [https://www.filforme.com/oquer(https://www.filforme.com/)

Email: [info@filforme.com] (mailto: info@filforme.com)

Pla Filament Test

I ordered 3 plans filament coils:

I took as color: black nebula, carrare marble and molecular aluminum.

In the package there was a temeo gray sample, a candy :-) and a advice for drying the filaments.

In the filament cardboard there is a vacuum plastic coil in a reusable bag, a new candy :-) A 3D print clip to block the filament and a dehumidifier bag.

I find that the packaging is above average.

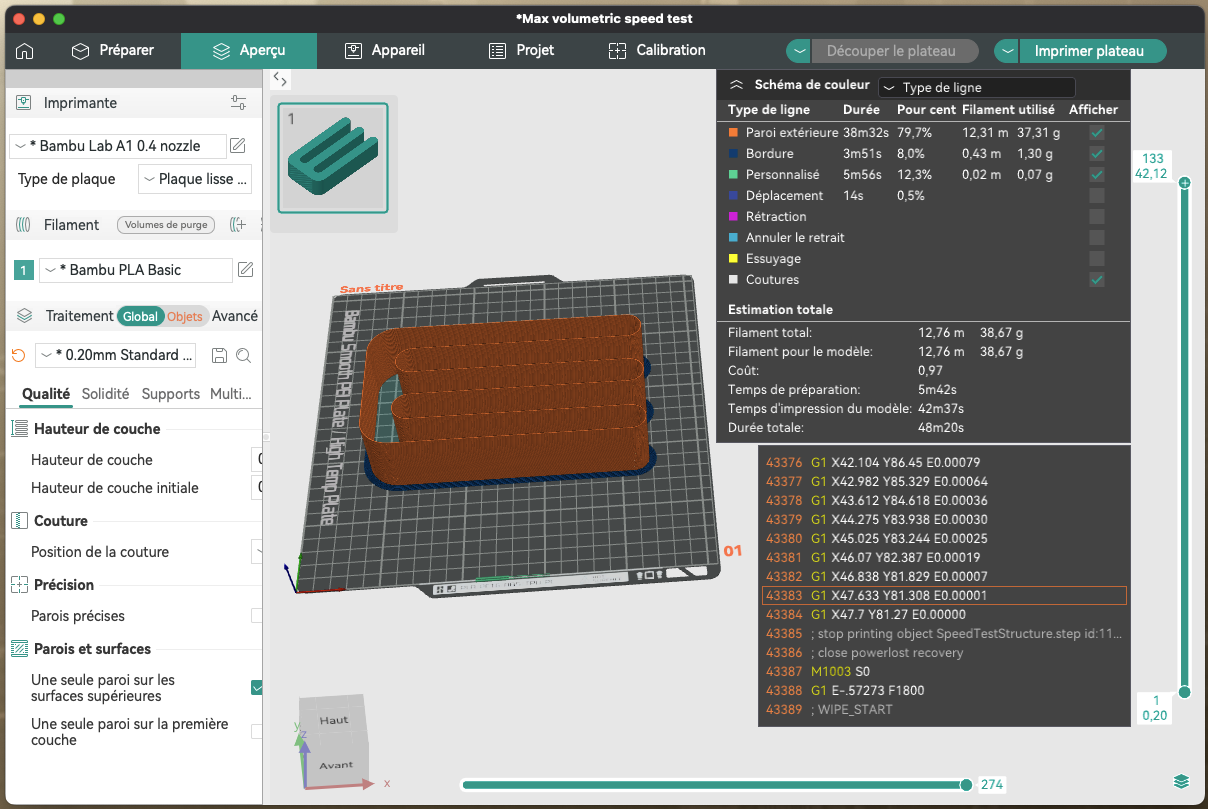

Maximum volumetric speed test

This test makes it possible to determine which rate maximum, you can extrude your filament

To carry out this test, I take ORCASLICER.

I carried out this test on the three filaments.

On the first two footprints, they support an impression with a maximum flow of 25 mm3/s, however, the third won from 23 mm3/s.

This test shows that these filaments are high speed filaments.

Filament diameter regularity test

To do this test I take the sample and I mass in several places the diameter with a slide foot.

The test shows that the filament respected well the diameter of the filament which is 1.75 mm.

I can do other test like a temperature tower, but I will stop it and start a few impressions using the bambu plaic profile which has a flow rate of 21mm3/s and for temperatures I put at 210 which is the max indicated on the coil.

Various printing tests

The first impression I made is a saucer for a vase.

Here are articulated animals that I have printed, no worries, the joints work well and the rendering is pretty.

Here are tests with objects that I modeled.

If you are interested, here is my MakerWorld page: [https://makerworld.com/en/@sgenosquoquoieîtps://makerworld.com/en/@sgenos)

I really like the marble effect.

Trick

On the label of the coil, he marked the weight of the empty coil so you can know what you have any filaments by weighing the coil and removing the empty weight.

Compatibility with AMS Lite

There is a quirk, the coil sinks into the left side of the AMS, but not on the right side, but no problem, it holds well.

I have not tested on the AMS of my P1S, but that should not pose any concern since the coil is plastic.

The price

It’s French, produced in France so it must be expensive!

No, the price is very correct 19 euros per plain coil, 26 euros per ASA coil, 25 euros per petg coil and 25 euros per coil.

Mondial relay delivery offered from 3kg.

Conclusion

I’m not going to go by 4 paths, it’s a very good plain filament, super print quality, quick printing, very good rendering.

Strengths:

Print quality

Packaging

The speed

The rendering

The indication of the weight of the vacuum coil

The price

Weak points:

The oddity on the AMS Lite but it is not embarrassing, I put it to find a weak point :-)

I will recommend filaments with them.

Good impression.