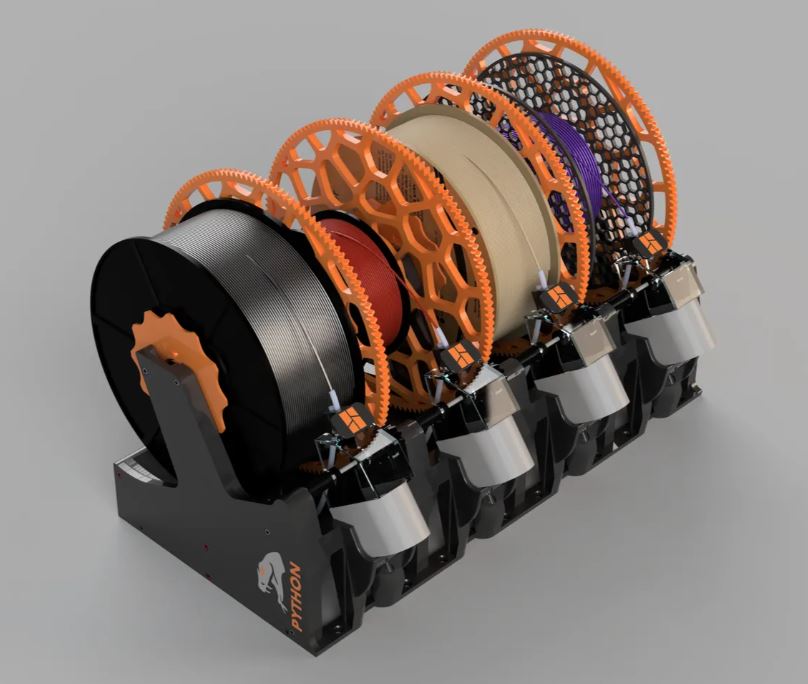

Python AMS

A multifunction and efficient AMS.

This mod is the work of humebeam , which was already the creator of the Mod Hydra AMS, which I used for almost a year.

But Python goes even further, completely thinking about the AMS system to optimize it, while keeping all the electronic components of AMS Bambulab.

Necessary materials:

1.5kg of petg

100g of TPU (optional for gears)

8 Rounds 608-Zzz4 Rollers 693-Zzzm3-8 mm: 20 pieces,

M3-10 mm: 7 pieces,

M3-16 mm: 9 pieces,

M3-25 mm: 9 parts

Ptfe bambulab

You have to count roughly 30 hours of printing to make the different parts of the MOD and 2 good hours of assembly by following the tutorial provided on the Python AMS download page.

Benefits

No more coil worries that get stuck or patina on the rollers

Compatible with all types of coils and sizes, up to about 80 mm wide and 210 mm in diameter

More AMS overload concerns

Possibility to use in external coil mode

Optional possibility of making a box with integrated drying or not

The gear system is well done and works perfectly

Access to AMS components without disassembly

Disadvantages:

Takes up more space than AMS Bambu Lab

A little noisier without box, slightly corrected with the gears in TPU

Non use of RFID chips

Use and tests

I used 1 Python AMS for a week, by making impressions every day, without meeting any worries, while on my 2nd P1S with the AMS Bambu Lab, I still met AMS overloads … So I quickly made the 2nd Python AMS!

After that I went on, many multi -colored impressions, large pieces, different filaments (PLA, PETG, ASA) successfully.

Just had a piece of filament stuck, but easily identifiable since you have access directly under the AMS to the PTFE.

150, 200 hours of printing on the 2 machines and it always works without error, it comforts me in my choice to have launched myself in this big modification ^^ and I now start in printing and assembly of boxes with passive drying

For the case, it takes about 1kg of Petg, 30 hours of printing, inserts threaded in M3, M3 screws and custom -made plexiglass.

But I am still in testing for the case, so surely an upcoming article with much more details to come 😊