Unlock, maintain and replace the extruder

Introduction

This complete guide shows you how to disassemble, clean, lubricate and replace the extruder of your 3D Bambu Lab printer (X1C, P1P/S).

These operations may be necessary if you meet:

- Extrusion problems

- Filament stuffing

- An underside

- An abnormal noise of the extruder

- Gear wear

Required tools

For maintenance

- 2 mm allen key

- Cruciform screwdriver

- Tweezers (optional)

- Isopropyl alcohol

- Used toothbrush

- Ptfe lubricant

- Clean cloth

For replacement

- New extruder (if necessary)

- Disassembly accessory (optional): [Makerworld] (https://makerworld.com/models/224756)

Preparation

Before you start

- ** Unload the filament ** from the extruder

- ** Turn off the printer ** and disconnect it from the sector

- ** Wait until the nozzle and the heating tray ** cool completely

- ** Remove the hotel ** if necessary

Remove the printer extruder

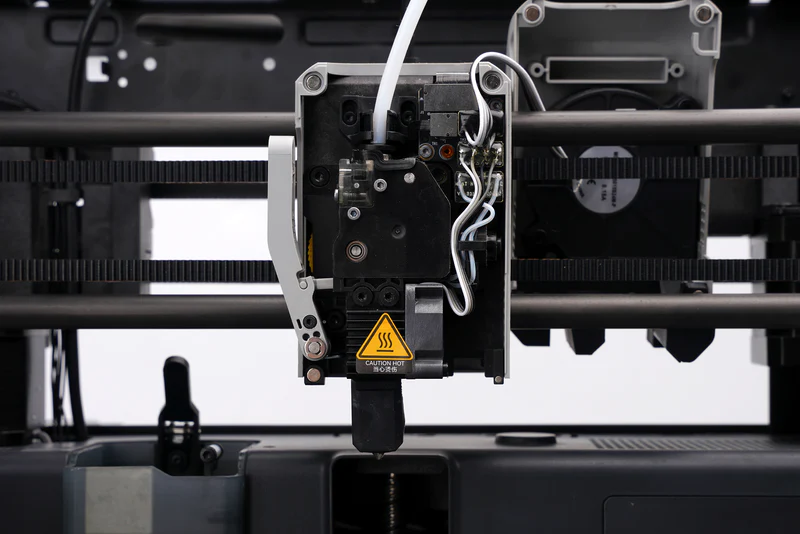

Step 1: Access the extruder

- Wait until the print head is cold to start the work

- Remove the cache from the print head

- Gently disconnect the cables

Step 2: Disassembly

- Remove the 3 screws using the 2 mm Allen key

- Disconnect the Card extruder cable

- Remove the printer extrude

Extruder interview

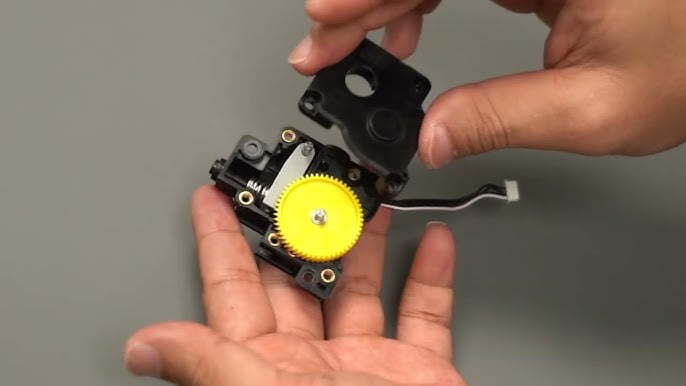

Dismantle

- Remove the four screws which fix the upper cover of the extruder

- Gently, remove the upper cover to reveal the internal gears

Clean the gears

- Loosen the small spring and remove the toothed wheel

- Remove the counter-engineering

- Clean the gears and other internal parts with isopropylic alcohol and a used toothbrush

- Dry all the parts well before reassembling them

Lubricate the gears

- Apply a thin layer of PTFE lubricant to the gears

- Make sure all the surfaces of the gears are uniformly lubricated

Go up the extruder

- Replace the toothed wheel and counter-engineering

- Return the spring to place and fix it with the screw

- Replace the upper cover and fix it with the four screws

Complete replacement of the extruder

If the maintenance is not enough or if the extruder is damaged, you can make a complete replacement.

Dismantle

Follow the disassembly steps above to remove the extruder.

Install the new extruder

- Place the new extruder in its accommodation

- Reconnect the extruder cable

- Attach the extruder with the 3 screws

- Return the hotel in place

Disassembly accessory

To facilitate disassembly, you can use the accessory available on Makerworld: [Link to the accessory] (https://makerworld.com/models/224756)

Put the extruder back in place

- Reconnect the extruder cable

- Follow the steps in the video “Change the nozzle on a 3D bambulab” printer to put the extruder back in place

Extruder calibration

After maintenance or replacement, it is important to calibrate the extruder:

- Turn on the printer and select the “Calibration” option from the menu

- Follow the instructions on the screen to calibrate the extruder

- Perform a print test to check that the extruder is working properly

Advice and precautions

Security

- Be careful when handling the gears because they can be cutting

- Do not use too much lubricant, as it could cause gears to skating

- Work in a clean environment to avoid contamination

Preventive maintenance

- Perform regular extruder maintenance (every 3-6 months depending on the use)

- Monitor abnormal noises that could indicate a problem

- Regularly check the condition of the gears

Technical support

If you encounter difficulties in dismantling or raising the extruder, do not hesitate to contact the technical support of Bambu Lab.

Conclusion

By following this complete guide, you should be able to disassemble, clean, lubricate and replace the extruder of your 3D Bambu Lab printer.

A regular maintenance of the extruder can:

- Solve extrusion problems

- Improve the quality of your impressions

- Extend the life of your printer

- Avoid expensive breakdowns

Do not forget to always make a calibration after any intervention on the extruder to guarantee optimal results.